| |

| Dry Polisher, KAPIKA

DP-3001 |

|

|

|

| |

| Dry Polisher, KAPIKA

DP-3001 |

|

|

|

Drive down both initial and running cost

Remove the residual bran by Dry polishing

input capacity

3,000-5,000 kg/h

Less residual bran on the ;

surface of milled rice

- Keeps the flavor longer

- Better appearance

- Easy to cook

- Less water pollution

- No water piping required at your facility

High milled rice recovery, Easy operation

The durablity of consumable parts is almost the same as our virtical

polisher.

Because of dry polisher, you ca save the initial cost as well as running cost.

The way of operation is same as polisher, it's very simple.

The broker rice during dry polishing is extremely less, you can get high

milled rice recovery.

Time saving & Cost reduction

Reduced 50 minutes for maintenance

(compare to previous model, DP-3000

Because of open structure, you can clean

the bran inside machine in 10 minutes.

For replacing the resistance part, you can

finish in 50 minutes (6 hours for DP-3000)

Screen Support section Main Shaft Section

Clean & Shiny

Without using water or any other material,

remove the 0.8% of residual bran (ration by

Weight).

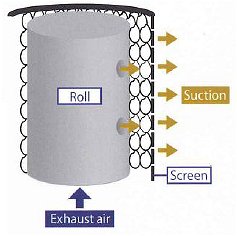

Set longer the length copare to roll's diameter,

retention time bcomes longer and remove the

bran throgh special processed screen.

By suction and exhaust fan, residual bran can be

released effectively.

The gap between screen and roll is narrow, 2 rice

grains, high effect of polishing can be achieved.

Physical property

*Whiteness was measured by KETT, C-300

*Turbidity was measured using recommended method of Japan Rice Millers Association.

*The results will vary slightly depanding on brown rice and milling process.

Rinsed rice water

Data from Japan Food Analysis Center

*Water quality was analyzed using the water after rice was washed.

For eash type of rice, 1.5kg of rice were washed three times using a total of 3.5 litre of water.

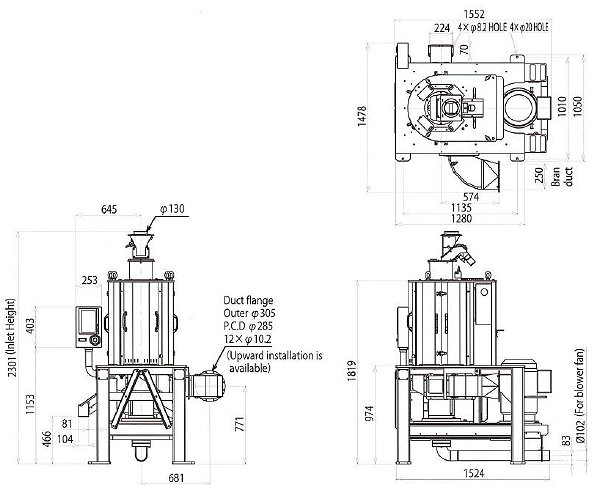

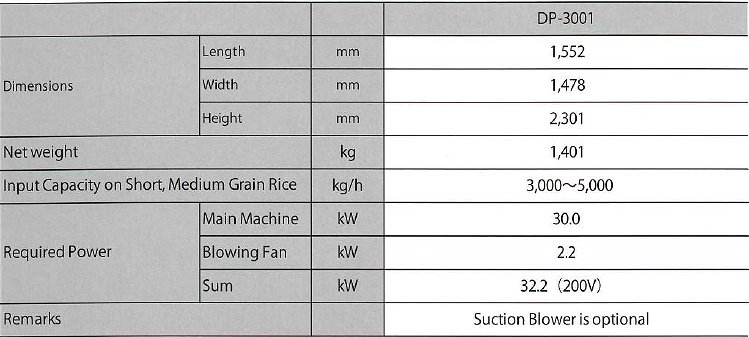

Dimension

Specifications Above specification and dimensions may change due to Yamamoto's continuous development program.

We create future of agriculture

YAMAMOTO CO.,LTD.

Email: calplus@earthlink.net

Calibration Plus 34 W. Hacienda Lane Woodland, CA 95695 Phone 530 662-7752 Fax 530 662-3998 Mobile, Voice Mail 530 848-2970